A single seam is easier to treat as a post process and has less issue with stop start of the filament flow. While some users found issues with the proprietary Cetus nozzles, and others mentioned that the cooling fan is loud, these qualms shouldn’t necessarily disqualify the Cetus 3D Printer from consideration, because this little machine has its strengths. This can contribute to small blobs on the print side as the flow is stopped and started in a new position. The biggest advantage to the Cetus 3D Printer is the build volume that the device offers. The seam you are seeing is the step to the next layer, usually there is an option to have random starts for new layers to try and hide the seam. I print about 20 or so of my calibration cubes per machine during a tune up. Hence my calibration cubes are printed direct onto 3M tape directly on the bed. What was the Z dimension on this two parts you made, are they identical ? Bit hard to measure as the raft can contribute to Z error. Color switches on ridges to form color transitions. Start enjoy the perspective-based color with Cetus2 and produce the most visually striking 3D prints. 1cm squares 5mm tall in different locations, map them and mark them before removing from the bed for comparison. Make your own dual-color co-extrusion prints, blend new colors that are not on the market, such as this mysterious pink, by co-extruding orange and blue at 50/50.

If it is that, then it maybe a limit you are stuck with.

Possibly a little spring in the table at that point that just adds a little squeeze to each layer printed. Slight difference in belt pitch or a pulley slightly off centre. The width difference could be put down to a combination of mechanical things working against you in that area.

Cetus3d slicer how to#

If anyone knows how to fix this, it would be greatly appreciated if you could provide me with some advice.Well the prints are pretty close to the ± 0.1mm tolerance. Now, I don't expect it to be able to hold water, but I have noticed that lots of the time, the infill is not solid and the top and bottom layers tend to have the slicer printing the following layer in the same direction, not crossed. The last issue I have seen is that many times, the layering is not watertight. There seems to be under extrusion near each of the "steps" of the model. The same issue occurs on all of the top layers of the object. Essentially, it splits up the single base into 5 separate bases. For an unknown reason, the slicer creates a "multi-layered" bottom layer. For example, on this model, which I have printed on a home built machine with no issues, it has a completely flat bottom. Cetus3D a brand of Tiertime.1765 Landess Ave.

Cetus3d slicer software#

The issue that I've been seeing is that there are weird layering issues. UP Studio 3 (Slicer) Wand (Host) 3rd Party Software Support: Yes, Cura, SuperSlicer, etc.

Parts list 8 2.74 Ohm 15W power resistors. Over-temperature protection independent of the temperature monitoring. Text 3dfused 3d printer dual fan 4fan adxl345 adxl345 mount bltouch bltouch mount bondtech ddx bondtech ddx v2 bondtech ddx v3 bontech bontech extruder cable strain relief copperhead creality creality ender 3 ddx direct drive.

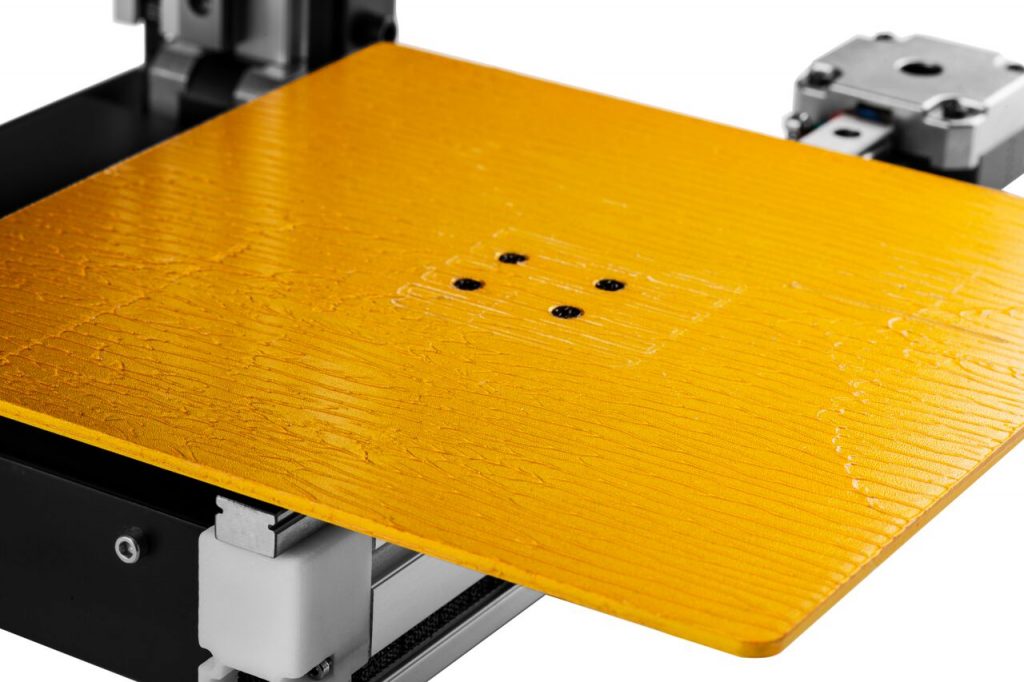

Whenever I slice something, I usually print with defaults in the advanced tab, so it usually prints a raft and supports unless I know the model doesn't need it. Speed: Lightening fast loading and slicing of large size STL files. DIY heated bed Design objectives: Ability to monitor and set the print bed temperature Use a separate power supply to that used by the 3D printer so as to not overload it. Text cetus3d holder mount tiertime z-probe. I have been able to start prints without even looking at the machine and I trust that it will complete the job, and it does! The only issue that I've run into that seems to be a software issue is with the slicer. I have had a lot of fun and great success printing with my Cetus3D printer recently.

0 kommentar(er)

0 kommentar(er)